Worm wheel type all-welded ball valve adopts fixed ball structure, the ball is equipped with bearings on the upper and lower shaft, the operating torque is small, the ball of this structure is fixed, the pressure does not move, the design has two sealing rings to provide sufficient preload force to ensure sealing, to achieve double-sided forced sealing, sealing performance is more reliable. The processing process of the ball has advanced computer detector tracking and detection, and the processing precision of the ball is high. Because the valve body material is the same as the pipeline material, there will be no uneven stress, and there will be no deformation due to earthquakes and vehicles passing through the ground, the sealing ring body is made of PTFE material containing 20%C(carbon) to ensure that there is no leakage .

All-welded ball valve is widely used in urban gas, urban heating, petrochemical, shipbuilding, steel, pressure regulating station, power plant and other pipeline equipment.

All-welded ball valve is an integral all-welded ball valve, there will be no external leakage and other phenomena, because the seat is composed of PTFE sealing ring and spring, so the pressure and temperature change adaptability, in the range of use will not produce any leakage. The processing process of the ball has advanced computer detector tracking and detection, and the processing precision of the ball is high. Because the valve body material is the same as the pipeline material, there will be no uneven stress, and there will be no deformation due to earthquakes and vehicles passing through the ground, and the pipeline is resistant to aging. The sealing ring body is made of PTFE with a content of 20%C(carbon) to ensure that there is no leakage.

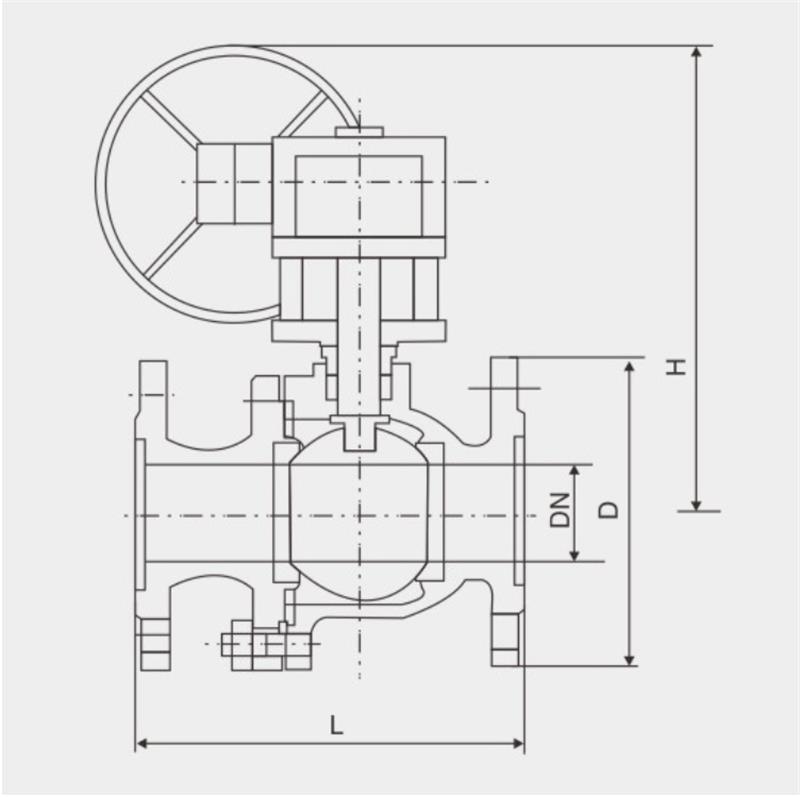

| DN(mm) | Nominal diameter | DH | d A/B |

t | L | H1 | H2 |

| 600 | 600 | 1016 | 610/630 | 22 | 1143 | 650 | 860 |

| 700 | 700 | 1130 | 7118720 | 24 | 1346 | 705 | 915 |

| 800 | 800 | 1245 | 813/820 | 28 | 1524 | 770 | 1000 |

| 900 | 900 | 1415 | 914/920 | 30 | 1727 | 855 | 1110 |

| 1000 | 980 | 1555 | 1016/1020 | 32 | 1840 | 925 | 1180 |

| 1100 | 1080 | 1700 | 1124 | 36 | 2100 | 995 | 1300 |

| 1200 | 1166 | 1860 | 1219/1220 | 40 | 2100 | 1075 | 1430 |

we will contact you in 6 hours as soon as we can.

We are factory.

Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

We adhere to strict quality control procedures that begin with product design and carry through to the end of the production process using state-of -the-art quality control equipment.

We are a global stocking valve distributor with a vast inventory of valves for any job.

Submit Request

PDF Request