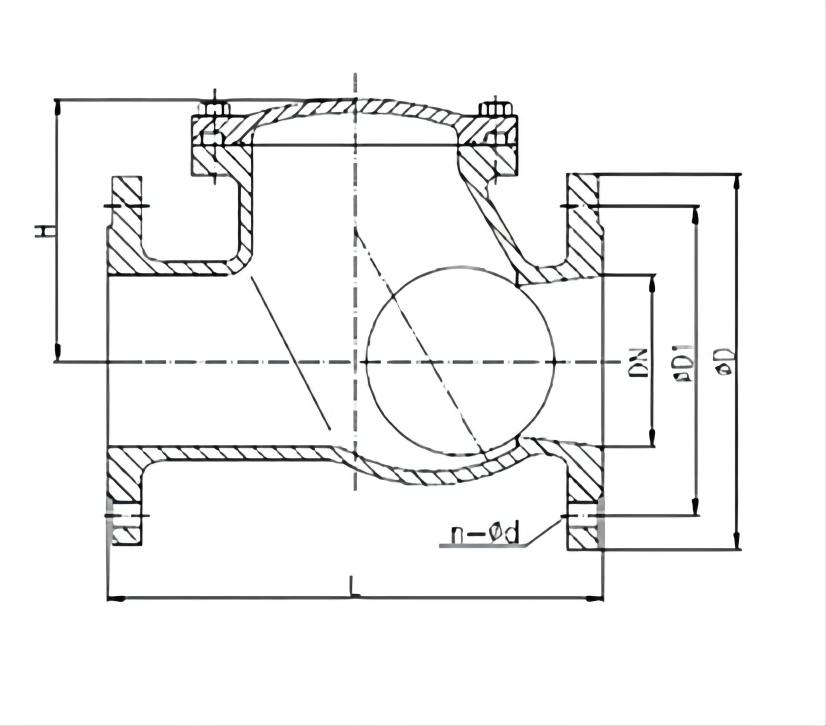

The check valve is a reverse fluid structure that uses multiple balls, channels, and cones. It consists of a front and back valve body, rubber ball, cone body, and other components.

The rubber ball is rolled briefly inside the ball cover to open and close the valve. When the pump is started, water is pressurised and flushes the rubber ball, causing it to roll to the right and fix the position of the cone body in the rear valve body, thus opening the check valve. When the pump stops, the return water pressure in the piping system forces the rubber ball to roll to the left front valve body, closing the check valve.

The rubber ball is made of a hollow steel ball, and the rubber's good elasticity ensures sealing and reduces damage to the pipeline system during valve closure. The cone body with holes fixes the steel ball when the valve is opened, eliminating pressure on the contact area between the rubber ball and the cone body. This results in surface contact, reducing hydraulic loss caused by the ball's shaking in the valve body.

We will contact you in 6 hours as soon as we can.

We are factory.

Generally it is 5-10 days if the goods are in stock. Or it is 15-20 days if the goods are not in stock, it is according to quantity.

We adhere to strict quality control procedures that begin with product design and carry through to the end of the production process using state-of -the-art quality control equipment.

We are a global stocking valve distributor with a vast inventory of valves for any job.

Submit Request

PDF Request