Forged steel stop valves are used in pipeline systems to close or open pipelines and keep the system running properly.

The globe valve, also called the closure door, is the most widely used valve, it is popular, because the friction between the sealing surface in the opening and closing process is small, more durable, the opening height is not large, easy to manufacture, convenient maintenance, not only for low pressure, but also for high pressure.

The closing principle of the globe valve is to rely on the pressure of the valve lever to make the sealing surface of the valve disc and the sealing surface of the valve seat closely fit to prevent the flow of the medium.

The globe valve only allows one-way flow of the medium and is directional when installed. The structural length of the globe valve is greater than that of the gate valve, and the fluid resistance is large, and the sealing reliability is not strong during long-term operation.

(1) The structure is simpler than the gate valve, and the manufacture and maintenance are more convenient.

(2) The sealing surface is not easy to wear and abrasion, good sealing, there is no relative slide between the valve disc and the valve body sealing surface when opening and closing, so the wear and abrasion are not serious, the sealing performance is good, and the service life is long.

(3) When opening and closing, the disc stroke is small, so the height of the stop valve is smaller than the gate valve, but the structural length is longer than the gate valve.

(4) The opening and closing torque is large, the opening and closing is more laborious, and the opening and closing time is the principal.

(5) The fluid resistance is large, because the medium channel in the valve body is more tortuous, the fluid resistance is large, and the power consumption is large.he valve body is made of precision casting and the precise geometry makes it possible to ensure the sealing of the valve without any other processing inside the valve.

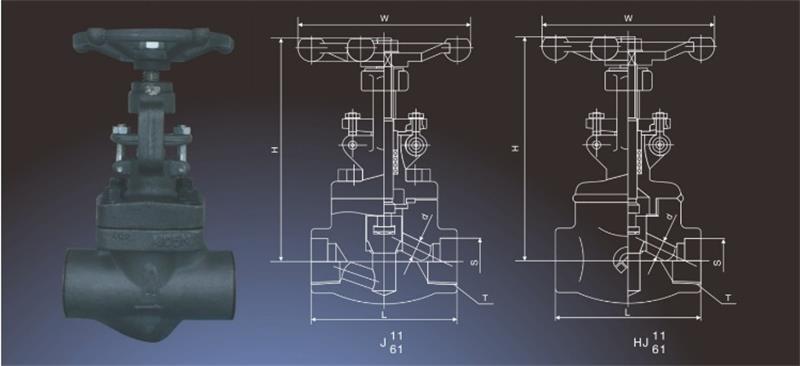

| DN(mm) | R.P | 8 | 10 | 15 | 20 | 25 | 32 | 40 | 50 |

| NPS(in) | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1V4 | 1-1/2 | 2 | |

| DN(mm) | F.P | — | 8 | 10 | 15 | 20 | 25 | 32 | 40 |

| NPS(in) | — | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | |

| d | R.P | 7 | 10 | 10 | 13 | 18 | 24 | 29 | 36.5 |

| F.P | — | 7 | 10 | 13 | 18 | 24 | 29 | 36.5 | |

| L | R.P | 79 | 79 | 79 | 92 | 111 | 120 | 152 | 172 |

| F.P | — | 79 | 79 | 92 | 111 | 120 | 152 | 172 | |

| H((turn on)H(Open) | R.P | 153 | 153 | 158 | 163 | 193 | 250 | 250 | 291 |

| F.P | — | 153 | 158 | 163 | 193 | 250 | 250 | 291 | |

| W | R.P | 100 | 100 | 100 | 100 | 125 | 160 | 160 | 180 |

| F.P | — | 100 | 100 | 100 | 125 | 160 | 160 | 180 | |

| WT(kg) | R.P | 1.9 | 1.8 | 1.7 | 2.1 | 3.3 | 7.5 | 7.5 | 11.4 |

| F.P | — | 2.1 | 1.9 | 2.3 | 3.6 | 7.8 | 8.2 | 12 |

we will contact you in 6 hours as soon as we can.

We are factory.

Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

We adhere to strict quality control procedures that begin with product design and carry through to the end of the production process using state-of -the-art quality control equipment.

We are a global stocking valve distributor with a vast inventory of valves for any job.

Submit Request

PDF Request