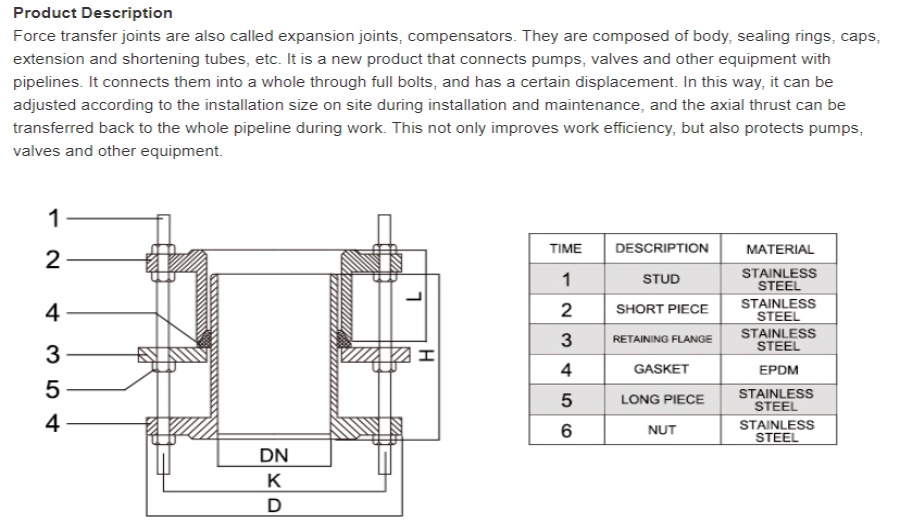

The force transfer joint is a new product for the connection of pump, valve, pipeline and other equipment with the pipeline, and connects them through the whole bolt to make it a whole, and has a certain amount of displacement, convenient installation. It can withstand the axial pressure of the pipeline. In this way, it can be adjusted according to the site installation size during installation and maintenance, and it not only improves work efficiency, but also plays a certain protective role in pipeline equipment such as pumps and valves.

The force transfer joint is an indispensable equipment in China's water purification and sewage industry. These substances are mainly transmitted through pipelines. In the process of pipeline transmission, gas, air, crude oil, fuel oil, domestic sewage, lubricating oil, fresh water, seawater, cold and hot water, drinking water, and refined oil products will certainly pass through the force transfer joint or the expansion joint. Then the connection is directly related to whether the entire pipeline system is a benign transmission process

1.Easy to install, easy to install the valve, can withstand the axial tension of the pipeline.

2. The product is composed of metal casting or welding, and the trapezoidal rubber sealing ring is selected for the loose sleeve part, under the action of the gland and bolts.

3. The use of rubber compression elastic deformation principle. The sealing ring is forced to deform between the outer wall of the expansion tube of the joint body for static sealing.

| DN | L (mm) | D (mm) | K (mm) | H (mm) | STUD | L (mm) | D (mm) | K (mm) | H (mm) |

| STUD | 40 | 180 | 150 | 110 | 330 | M16x4 | 180 | 150 | 110 |

| 330 | M16x4 | 50 | 180 | 165 | 125 | 330 | M16x4 | 180 | 165 |

| 125 | 330 | M16x4 | 65 | 180 | 185 | 145 | 330 | M16x4 | 180 |

| 185 | 145 | 330 | M16x4 | 80 | 200 | 200 | 160 | 350 | M16x8 |

| 200 | 200 | 160 | 350 | M16x8 | 100 | 200 | 220 | 180 | 350 |

| M16x8 | 200 | 220 | 180 | 350 | M16x8 | 125 | 200 | 250 | 210 |

| 350 | M16x8 | 200 | 250 | 210 | 350 | M16x8 | 150 | 200 | 285 |

| 240 | 350 | M20x8 | 200 | 285 | 240 | 350 | M20x8 | 200 | 220 |

| 340 | 295 | 380 | M20x8 | 220 | 340 | 295 | 380 | M20x12 | 250 |

| 220 | 400 | 350 | 380 | M20x12 | 230 | 400 | 355 | 400 | M24x12 |

| 300 | 220 | 455 | 400 | 390 | M20x12 | 250 | 455 | 410 | 420 |

| M24x12 | 350 | 230 | 505 | 460 | 400 | M20x16 | 260 | 520 | 470 |

| 440 | M24x16 | 400 | 230 | 565 | 515 | 410 | M24x16 | 270 | 580 |

| 525 | 460 | M27x16 | 450 | 250 | 615 | 565 | 430 | M24x20 | 270 |

| 640 | 585 | 470 | M27x20 | 500 | 260 | 670 | 620 | 450 | M24x20 |

| 280 | 715 | 650 | 490 | M30x20 | 600 | 260 | 780 | 725 | 460 |

| M27x20 | 300 | 840 | 770 | 520 | M33x20 | 700 | 260 | 895 | 840 |

| 460 | M27x24 | 300 | 910 | 840 | 520 | M33x24 | 800 | 290 | 1010 |

| 950 | 500 | M30x24 | 320 | 1025 | 950 | 550 | M36x24 | 900 | 290 |

| 1115 | 1050 | 500 | M30x28 | 320 | 1125 | 1050 | 560 | M36x28 | 1000 |

we will contact you in 6 hours as soon as we can.

We are factory.

Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

We adhere to strict quality control procedures that begin with product design and carry through to the end of the production process using state-of -the-art quality control equipment.

We are a global stocking valve distributor with a vast inventory of valves for any job.

Submit Request

PDF Request